BFW Trending

Company and industry insights

Learn more about our projects and customers, events and conferences, BFW organization updates, and the latest product news by visiting our knowledge zone.

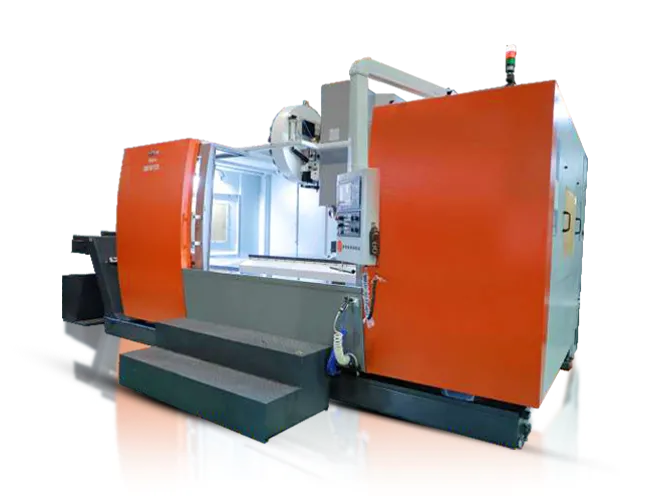

Designed for better surface finishing, cycle time, and process capabilities for various uses.

XTRON Series is developed for high productivity, performance & ergonomic features.

Agni + was built to enhance shop-floor productivity and batch-production efficiency.

C-Frame construction with rigid bases, robust spindle, and high-precision feed mechanism.

BMV 60+ series is ideal for machining small to medium-size applications for batch production.

The rigid structure, small footprint, and precise spindle ensure a high-quality performance.

The rigid structure of the Astra has been created specifically for cost-effective machining.

BMV 80 features linear motion guide-ways and variable speed AC spindle drives.

Contact us online or join us at one of our events to explore potential partnerships and collaborations. Our custom solutions are manufactured using cutting-edge technologies and the latest methodologies.

Ready-made VMC machine and VMC machine solutions offer a comprehensive range of options for businesses seeking a cost-efficient approach to enhancing manufacturing capabilities without the need for custom manufacturing.

A Fixed-Column Vertical Machining Center (VMC) is a type of CNC (Computer Numerical Control) machine where the column, which supports the spindle, remains stationary while the table holding the workpiece moves along the X and Y axes. The spindle, mounted on the fixed column, moves vertically along the Z axis. This setup is ideal for operations requiring high precision, rigidity, and stability.

Stability and Rigidity: The fixed column provides exceptional stability, reducing vibrations during machining. This results in more accurate and precise cuts, making it suitable for detailed and complex work on smaller components.

Precision: With the column being stationary, the machine maintains high levels of precision, making it ideal for industries that require fine tolerances, such as aerospace, automotive, and electronics.

Ease of Use: The design allows for easy programming and operation, which can be particularly beneficial in small-batch or prototype production where setup times need to be minimized.

Space Efficiency: Fixed-column VMCs often occupy less floor space compared to other machine configurations, making them suitable for smaller workshops or production areas with space constraints.

Cost-Effective: Generally, fixed-column VMCs are less expensive to purchase and maintain compared to movable-column machines, offering a cost-effective solution for precision machining.

Operator-Friendly Design: The fixed column enhances visibility and ease of access for operators, simplifying the setup and monitoring process, which can reduce errors and improve overall productivity

Aerospace industry: In the aerospace industry, fixed-column Vertical Machining Centers (VMCs) are vital for producing complex components like engine parts and turbine blades, where precision and stability are crucial to meet strict quality standards. Their ease of programming also makes them ideal for prototyping, allowing engineers to quickly develop and refine new aerospace designs.

Automotive industry: Fixed-column Vertical Machining Centers (VMCs) are crucial in the automotive industry for manufacturing high-precision components such as engine blocks, transmission cases, and cylinder heads, where maintaining tight tolerances is essential. Additionally, these machines excel in producing custom and low-volume parts, ensuring consistent precision and quality across all production runs.

Electronics industry: Fixed-column Vertical Machining Centers (VMCs) are essential in the electronics industry for producing small, precise components like connectors, housings, and heat sinks, where accuracy is critical to meet exact specifications. These machines also support efficient prototyping and small-batch production, allowing for quick iterations during the development of new electronic designs.

Mold and die industry: In mold and die making, fixed-column Vertical Machining Centers (VMCs) are crucial for achieving the high level of accuracy needed to create detailed and precise molds. These machines are particularly adept at machining complex surfaces and contours, which are essential for producing intricate patterns and designs required in industries like plastic injection molding and metal casting.

Medical device industry: When it comes to the medical device industry, fixed-column VMCs are indispensable for manufacturing surgical instruments, orthopedic implants, and other medical devices where both precision and biocompatibility are critical. These machines also enable rapid prototyping, offering the flexibility needed to efficiently create and refine new medical designs.

General manufacturing: For general manufacturing, the versatility of fixed-column VMCs makes them valuable tools for producing custom parts and prototypes across a wide range of industries. Their ability to handle various materials and execute intricate designs ensures they are a reliable asset in any manufacturing environment.

Learn more about our projects and customers, events and conferences, BFW organization updates, and the latest product news by visiting our knowledge zone.

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon