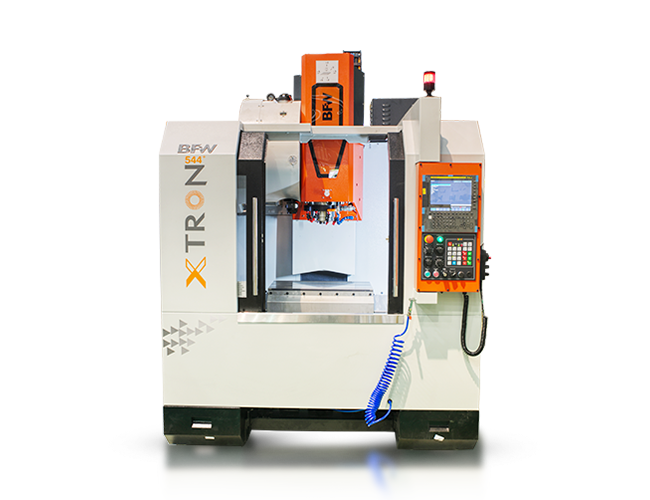

“To match the demand of greater accuracy and total reliability at higher speeds, BFW has developed XTRON Series Vertical Machining centers. These machines are rigid base C-type machines with moving table for easy access. The high dynamic structure supports rapid axis take-offs with a higher acceleration.”

XTRON Series – Next-gen VMCs, engineered for enhanced machining performance.

| Capacity | |||||||||

| Unit | XTRON-433 | XTRON-544 | XTRON-755 | XTRON-955 | XTRON-1166 | XTRON-1366 | XTRON-1577 | ||

| Table Longitudinal travel (X-Axis) | mm | 400 | 500 | 700 | 900 | 1100 | 1300 | 1500 | |

| Table cross travel (Y-Axis) | mm | 300 | 400 | 500 | 500 | 600 | 600 | 700 | |

| Head stock travel (Z-Axis) | mm | 300 | 400 | 500 | 500 | 600 | 600 | 700 | |

| Spindle nose face to table top | mm | 150-450 | 150-550 | 100-600 | 100-600 | 150-750 | 150-750 | 150-850 | |

| Increased daylight area with column height block (Optional) | mm | 350-650 | 350-750 | 300-800 | 300-800 | 350-950 | 350-950 | 450-1150 | |

| Distance from floor to table top (front chip disposal) | mm | 850 | 900 | 950 | 950 | 1000 | 1000 | 1050 | |

| Spindle center – column front distance | mm | 390 | 480 | 540 | 540 | 660 | 660 | 735 | |

| Table | |||||||||

| XTRON-433 | XTRON-544 | XTRON-755 | XTRON-955 | XTRON-1166 | XTRON-1366 | XTRON-1577 | |||

| Table size | mm | 600 *310 | 700 * 410 | 900 * 510 | 1100 * 510 | 1300 * 610 | 1500 * 610 | 1700 * 710 | |

| T-slot (No./size/ pitch) | No/ mm/ | 3/14/'80 | 3/ 14/ 150 | 5/ 18/ /100 | 5/ 18/ /100 | 5/ 18/ /100 | 5/ 18/ /100 | 5/ 18/ /125 | |

| Maximum load on table standard | Kg | 250 | 500 | 900 | 900 | 1300 | 1300 | 1500 | |

| Spindle and Axes- XTRON 544, XTRON 755, XTRON 955 | |||||||||

| Spindle: | Unit | XTRON-433 | XTRON-544 | XTRON-755 | XTRON-955 | ||||

| Belt Driven (Std) | Taper | Type | BT40 | BT40 | BT40 | BT50 | BT40 | BT50 | |

| Speed | rpm | 8000 (10000) (6000) | 8000 (10000) (6000) | 8000 (4800)(6000) (10000) | 6000 (4800) | 8000 (4800)(6000) (10000) | 6000 (4800) | ||

| Fanuc Mitsubishi Cont./ 30 min | kW | 5.5/ 7.5 | 5.5/ 7.5 | 7.5/ 11 | 7.5/ 11 | ||||

| Siemens S1/S6-40% (Option) | kW | 5.5/ 8.3 | 5.5/ 8.3 | 9/ 13.5 | 9/ 13.5 | ||||

| Belt Driven High Power (Option) | Taper | Type | NA | BT40 | BT40 | BT50 | BT40 | BT50 | |

| Speed (opt 1) (opt 2) | rpm | NA | 8000(6000) | 8000 (6000) (10000) | 6000 (4800) | 8000 (6000) (10000) | 6000 (4800) | ||

| Fanuc/ Mitsubishi Cont/ 30 min | kW | NA | 7.5/11 | 11/15 | 11/15 | 11/15 | 11/15 | ||

| Siemens S1/S6/ 40% | kW | NA | NA | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | ||

| Belt Driven High Power High Torque (Option) | Taper | Type | NA | NA | BT40 | BT50 | BT40 | BT50 | |

| Speed | rpm | NA | NA | 6000 (4800) | 6000 (4800) | 6000 (4800) | 6000 (4800) | ||

| Fanuc | kW | NA | NA | P – Series (P22) | P – Series (P22) | ||||

| In line Drive (Option) | Taper | Type | NA | BT40 | BT40 | NA | BT40 | NA | |

| Fanuc/ Mitsubishi Cont/ 30 min | kW | NA | 5.5/ 7.5 | 7.5/ 11 | NA | 7.5/ 11 | NA | ||

| Siemens $1/ S6-40% | kW | NA | 5.5/ 8.3 | 9/ 13.5 | NA | 9/ 13.5 | NA | ||

| Speed (option 1) | rpm | NA | 10000 (12000) | 10000 (12000) | NA | 10000 (12000) | NA | ||

| Gear box (Option) | Taper | Type | NA | NA | NA | NA | NA | NA | |

| Speed | rpm | NA | NA | NA | NA | NA | NA | ||

| Fanuc/ Mitsubishi Cont, 30 min | kW | NA | NA | NA | NA | NA | NA | ||

| Siemens S6/ 40% | kW | NA | NA | NA | NA | NA | NA | ||

| Spindle and Axes- XTRON 1166,XTRON 1366,XTRON 1577 | |||||||||

| Spindle: | Unit | XTRON-1166 | XTRON-1366 | XTRON-1577 | |||||

| Belt Driven (Std) | Taper | Type | BT40 | BT50 | BT40 | BT50 | BT40 | BT50 | |

| Speed | rpm | 6000 (8000) (4800) | 6000 (4800) | 6000 (8000) (4800) | 6000 (4800) | 6000 (8000) (4800) | 6000 (4800) | ||

| Fanuc Mitsubishi Cont./ 30 min | kW | 7.5/ 11 | 7.5/ 11 | 7.5/ 11 | 7.5/ 11 | 7.5/ 11 | 7.5/ 11 | ||

| Siemens S1/S6-40% (Option) | kW | NA | NA | NA | NA | NA | NA | ||

| Belt Driven High Power (Option) | Taper | Type | BT40 | BT50 | BT40 | BT50 | BT40 | BT50 | |

| Speed (opt 1) (opt 2) | rpm | 6000 (8000) (4800) | 6000 (4800) | 6000 (8000) (4800) | 6000 (4800) | 6000 (8000) (4800) | 6000 (4800) | ||

| Fanuc/ Mitsubishi Cont/ 30 min | kW | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | ||

| Siemens S1/S6/ 40% | kW | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | ||

| Belt Driven High Power High Torque (Option) | Taper | Type | BT40 | BT50 | BT40 | BT50 | BT40 | BT50 | |

| Speed | rpm | 6000 (4800) | 6000 (4800) | 6000 (4800) | 6000 (4800) | 6000 (4800) | 6000 (8000) | ||

| Fanuc | kW | P – Series (P22) | P – Series (P22) | P – Series (P22) | |||||

| In line Drive (Option) | Taper | Type | NA | NA | NA | NA | NA | NA | |

| Fanuc/ Mitsubishi Cont/ 30 min | kW | NA | NA | NA | NA | NA | NA | ||

| Siemens $1/ S6-40% | kW | NA | NA | NA | NA | NA | NA | ||

| Speed (option 1) | rpm | NA | NA | NA | NA | NA | NA | ||

| Gear box (Option) | Taper | Type | BT40 | BT50 | BT40 | BT50 | BT40 | BT50 | |

| Speed | rpm | 4500 (6000) | 4500 (6000) | 4500 (6000) | 4500 (6000) | 4500 (6000) | 4500 (6000) | ||

| Fanuc/ Mitsubishi Cont, 30 min | kW | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | 11/15 | ||

| Siemens S6/ 40% | kW | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | 11/ 16.5 | ||

| Automatic Tool Changer: Twin Arm- XTRON 544,XTRON 755,XTRON 955 | |||||||||

| Unit | XTRON-433 | XTRON-544 | XTRON-755 | XTRON-955 | |||||

| BT40 | BT40 | BT40 | BT50 | BT40 | BT50 | ||||

| Number of Tools | No | 20 | 24 | 24 | 30 | 20 | 24 | 30 | 20 |

| Pul stud-MAS 403 | type | P40 T – 1 | P40 T – 1 | P40 T – 1 | P50 T – 1 | P40 T – 1 | P50 T-1 | ||

| Maximum tool dia with all pockets ful | mm | 80 | 75 | 75 | 75 | 130 | 75 | 75 | 130 |

| Max tool dia adjacent pockets empty | mm | 125 | 140 | 140 | 140 | 220 | 140 | 140 | 220 |

| Maximum tool length | mm | 200 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Maximum tool weight | kg | 8 | 8 | 8 | 7 | 15 | 8 | 7 | 15 |

| Tool to tool time | Sec | 2.5 | 2.5 | 2.5 | 2.5 | 4.5 | 2.5 | 2.5 | 4.5 |

| Automatic Tool Changer: Twin Arm- XTRON 1166, XTRON 1366, XTRON 1577 | |||||||||

| Unit | XTRON-1166 | XTRON-1366 | XTRON-1577 | ||||||||

| BT40 | BT50 | BT40 | BT50 | BT 40 | BT 50 | ||||||

| Number of Tools | No | 24 | 30 | 20 | 24 | 30 | 20 | 24 | 30 | 20 | |

| Pul stud-MAS 403 | type | P40 T – 1 | P50 T-1 | P40 T-1 | P50 T-1 | P40 T-1 | P50 T-1 | ||||

| Maximum tool dia with all pockets ful | mm | 75 | 75 | 130 | 75 | 75 | 130 | 75 | 75 | 130 | |

| Max tool dia adjacent pockets empty | mm | 140 | 140 | 220 | 140 | 140 | 220 | 140 | 140 | 220 | |

| Maximum tool length | mm | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 | |

| Maximum tool weight | kg | 8 | 7 | 15 | 8 | 7 | 15 | 8 | 7 | 15 | |

| Tool to tool time | Sec | 2.5 | 2.5 | 4.5 | 2.5 | 2.5 | 4.5 | 2.5 | 2.5 | 4.5 | |

| Automatic Pallet Changer(optional) | ||||||||

| Unit | XTRON 433 | XTRON 544 | XTRON 755 | XTRON 955 | XTRON 1166 | XTRON 1366 | XTRON 1577 | |

| Number of Pallets | No | NA | 2 | 2 | 2 | 2 | 2 | 2 |

| Pallets Size | mm * mm | NA | 380 * 600 | 480 * 800 | 480 * 1000 | 580 * 1200 | 580 * 1400 | 680 * 1600 |

| T – slot (No./Size/Pitch) | No/mm/m | NA | 3/14/0150 | 3/18/0150 | 3/18/0150 | 5/18/100 | 5/ 18/ 100 | 5/ 18/ 125 |

| Distance from the Pallet top (front Chip conveyor) | mm | NA | 1050 | 1200 | 1250 | 1200 | 1200 | 1250 |

| Maximum Safe load per Pallet | kg | NA | 300 | 400 | 500 | 600 | 700 | 800 |

| Accuracy as per ISO 230-2 | ||||||||

| Accuracy as per ISO 230-2 | Unit | XTRON 433 | XTRON 544 | XTRON 755 | XTRON 955 | XTRON 1166 | XTRON 1366 | XTRON 1577 |

| Positioning | mm | 0.010 | 0.010 | 0.012 | 0.012 | 0.016 | 0.016 | 0.016 |

| Repeatability | mm | 0.007 | 0.007 | 0.009 | 0.009 | 0.012 | 0.012 | 0.012 |

| Installation Data | ||||||||

| Unit | XTRON 433 | XTRON 544 | XTRON 755 | XTRON 955 | XTRON 1166 | XTRON 1366 | XTRON 1577 | |

| Floor space (W x D) | mm * mm | 1700*2010 | 2050*2450 | 2500*2450 | 2500*2450 | 3100*2700 | 3600*2700 | 4000*2950 |

| Machine height (H) | mm | 2500 | 2730 | 2900 | 2900 | 3300 | 3300 | 3450 |

| Basic machine weight (Approx) | kg | 2500 | 4000 | 5000 | 5200 | 7900 | 8200 | 10000 |

| Total connected load (Basic machine) | KVA | 12 | 18 | 22 | 28 | 22 | 28 | 28 | 28 | 28 | 28 | 28 | 28 |

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download our comprehensive product brochure and learn how our products should support your needs.