FX series has been developed on the proven platform of ORION series Horizontal Machining Centers.

Innovated to meet the configuration for the Balance of precision and speed for complex precision parts machining and import substitution. Introduced to meet the demand for World-class HMCs for the Indian and global market.

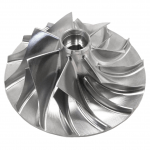

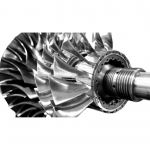

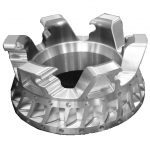

ORION Fx series is extensively applied to the industries of aerospace, automotive, medical, energy, and further more.

Fx series are developed for high performance manufacturing solutions & guarantees double in your returns

| Specifications | Unit | Fx5500 | Fx8000 | Fx10000 |

| Axis | ||||

| X axis | mm | 800 | 1250 | 1600 |

| Y axis (Table) | mm | 1000 | 1250 | 1400 |

| Z axis (Spindle) | mm | 800 | 1000 | 1250 |

| Work volume XYZ | 3 m | 0.64 | 1.25 | 2.5 |

| Rapid traverse | m/ min | 60 | 40 | 40 |

| Acceleration | 2 m/ S | 6 | 4 | 4 |

| Table | ||||

| Rotary table - Direct Drive | posn | 360,000 x 0.001deg | 360,000 x 0.001deg | 360,000 x 0.001deg |

| Table speed | rpm | 40 | 20 | 10 |

| Pallet size | mm | 500 x 500 | 630 x 630 (800 x 800) | 1000 x 1000 |

| Load capacity | kg | 700 | 1500 | 3000 |

| Max. Job swing dia x swing height | mm | 800 x 1000 | 1250 x 1200 | 1600 x 1400 |

| Spindle | ||||

| Spindle taper std. | HSK A63 | HSK A100 | HSK A100 | |

| Spindle power Ed40% std. | kW | 28 | 63 | 63 |

| Spindle speed std. | Nm | 12000 | 8000 | 8000 |

| Max spindle torque std. | Nm | 105 | 470 | 470 |

| Spindle taper (high speed opt) | - | HSK A63 | HSK A63 | |

| Spindle power ED40% (high speed opt) | kW | - | 28 | 28 |

| Spindle speed (high speed opt.) | rpm | - | 12000 | 12000 |

| Max spindle torque (high speed opt) | Nm | - | 105 | 105 |

| Swivelling Milling Head | ||||

| Rotating speed Cont./ 50% ED | mm | 10 | 10 | 10 |

| Axis torque | mm | 3,000 | 5,000 | 5,000 |

| Resolution | deg | 0.001 | 0.001 | 0.001 |

| Automatic tool changer | ||||

| Number of tools std | 60 | 60 | 60 | |

| Number of tools opt | 80 | 80-120 | 80-120 | |

| Max tool diameter all places | mm | 80 | 125 | 125 |

| Max tool diameter max | mm | 165 | 250 (315) | 250 (315) |

| Max tool length | mm | 430 | 600 | 600 |

| Max tool weight | kg | 12 | 30 | 30 |

| Chip to chip time (min) | s | 4 | 7.5 | 8.7 |

| Pallet changer | ||||

| Type | 180 deg swing type | |||

| Pallet change time | s | 10 | 25 | 60 |

| Accuracy as per ISO 230-2 | ||||

| Positioning A - with Linear scale | mm | 0.008 | 0.008 | 0.009 |

| Repeatability R - with Linear scale | mm | 0.005 | 0.005 | 0.007 |

| B & C axis index accuracy | arcsec | 10 | 10 | 12 |

| Machine Installation Data (With Pallet Changer) | ||||

| Basic machine weight | kg | 14000 | 24000 | 30000 |

| Floor area W x D | mm | 3200x5800 | 4250x7000 | 4500x9500 |

| Compressed Air | bar | 5-6 | 5-6 | 5-6 |

| Total connected load-cont/ 30 min | kVA | 60 | 90 | 100 |

| Power supply | 3ph, 415 V, 50 Hz | |||

| CNC system | Siemens Sinumerik 1(Simultaniuos 5 axis) | |||

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download our comprehensive product brochure and learn how our products should support your needs.