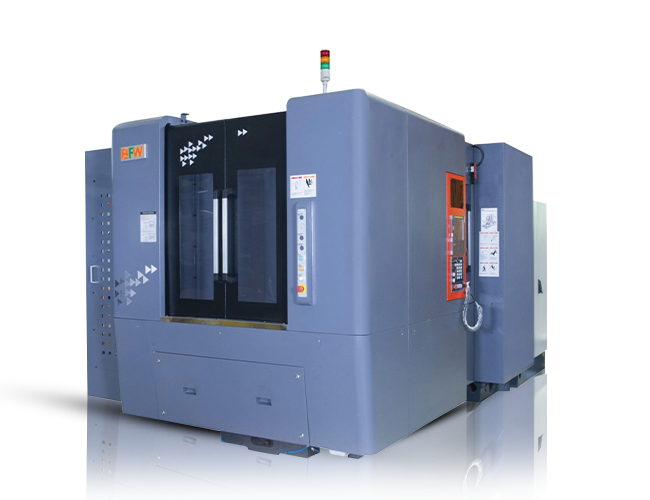

Prima Pro series of Horizontal Machining Centers seamlessly combine our decades of experience in building HMCs with valuable feedback from our customers. It takes the HMC series to the next level in reliability, performance, and productivity.

Prima takes from the word “primary” indicating a thing/person who has an overriding impact on everything around it.

Spindle & Axes

| Spindle | Unit | Prima 44 Pro | Prima 54 Pro | Prima 55 Pro | Prima 65 Pro |

| Spindle taper – Std. (Option) | Type | BT40 (HSK A63) | BT40 (HSK A63) | BT50 (HSK A 100) | BT50 (HSK A 100) |

| Spindle Power & torque (cont./int.)- std | kW | 15/18.5 , 143/235 Nm | 15/18.5, 190/310 Nm | 22/22, 365/498 Nm | |

| Spindle speed- Standard (option) | rpm | 6000 (8000) | 6000 (8000) | 6000 | 6000 |

| Axes | |||||

| X / Y / Z axes | mm | 600/600 /600 | 800/700 /800 | 800/700 /800 | 1000/850 /1000 |

| Feed Rate | mm/min | 1-20000 | 1-20000 | 1-20000 | 1-20000 |

| Rapid Traverse | m/min | 40 | 40 | 40 | 40 |

| Pallet top to spindle centre (min./max) | mm | 100-700 | 100-800 | 100-800 | 120-970 |

| Pallet centre to spindle face (min./max) | mm | 100-700 | 60-860 | 60-860 | 150-1050 |

Index Table/Rotary Table

| Index Table/ Rotary Table | Unit | Prima 44 Pro | Prima 54 Pro | Prima 55 Pro | Prima 65 Pro |

| Pallet size | mm | * 00 | 630*500 | 630*500 | 800*630 |

| Pallet type | Tapped holes (M16*34) | T-slot | |||

| Load Capacity | kg | 400 | 500 | 500 | 1000 |

| Maximum job size (dia*height) | mm | 630*650(700 with restriction) | 700*800 (800 with restriction) | 700*800 (800 with restriction) | 1050*1300 |

| Index positions Std(Option) | deg | 360*1deg (720*0.5 deg) | |||

| NC Rotary table- Option | deg | 360,000 *0.001 deg | |||

Automatic Tool Changer

| Automatic Tool Changer | Unit | Prima 44 Pro | Prima 54 Pro | Prima 55 Pro | Prima 65 Pro |

| No of tools- Std(Option 1, Option 2) | No | 24(40)(60) | 24(40)(60) | 40(60) | 40 | 60 |

| Max tool dia with all pockets full | mm | 75 | 75 | 125 | 125 |

| Max tool dia with all adjacent pockets empty | mm | 125 | 125 | 225 | 225 | 250/315 |

| Maximum tool length | mm | 300 | 300 | 400 | 450 | 500 |

| Tool weight | kg | 7 | 7 | 15(40 tools) | 25(60 tools) | 15 | 25 |

| Tool change time | sec | 2.2 | 2.2 | 3.5 | 4 |

| Chip to chip time(mm) as per ISO 10791-9 | sec | 5.9 | 6.5 | 8.5 | 9.5 |

| Pull stud | MAS 403 PT 40-1 | MAS 403 PT 40-1 | MAS 403 PT 50-1 | MAS 403 PT 50-1 |

Accuracy as per ISO 230-2

| Accuracy as per ISO 230-2 | Unit | Prima 44 Pro | Prima 54 Pro | Prima 55 Pro | Prima 65 Pro |

| Linear axes | |||||

| Positioning A | mm | 0.010 | 0.010 | 0.010 | 0.010 |

| Repeatability R | mm | 0.008 | 0.008 | 0.008 | 0.008 |

| B axis - Index Table | |||||

| Positioning A | arc sec | 8 | 8 | 8 | 8 |

| Repeatability R | arc sec | 6 | 6 | 6 | 6 |

| B axis - Rotary Table | |||||

| Positioning A | arc sec | 12 | 12 | 12 | 12 |

| Repeatability R | arc sec | 9 | 9 | 9 | 9 |

Automatic pallet changer | CNC System

| Unit | Prima 44 | Prima 54 | Prima 55 | Prima 65 | |

| Automatic Pallet Changer | 180° Swing Type | 180° Swing Type | 180° Swing Type | 180° Swing Type | |

| CNC System | Mitsubishi (Fanuc 0i MF+) | Mitsubishi (Fanuc 0i MF+) | Mitsubishi (Fanuc 0i MF+) | Mitsubishi (Fanuc 0i MF+) |

Installation Data

| Installation Data | Unit | Prima 44 | Prima 54 | Prima 55 | Prima 65 |

| Basic weight of machine | kg | ~10,000 | ~13,500 | ~14,000 | ~20,000 |

| Floor area for Std. machine W x D | mm | ~2400 x 6300 | ~2850 x 6550 | ~3000 x 6550 | ~3450 x 7430 |

| Total connected load | kVA | ~ 35 | ~ 45 | ~ 48 | ~ 60 |

| Compressed air | bar | 6 | 6 | 6 | 6 |

| Power Supply | 415 V± 10% AC, 50 ± 2% Hz, 3 phase | ||||

A general purpose HMC (Horizontal Machining Center) is a type of CNC (Computer Numerical Control) machine used in manufacturing for precision machining. Unlike vertical machining centres, where the spindle is oriented vertically, an HMC has a horizontally oriented spindle. This allows for the workpiece to be machined from multiple sides without needing to be manually repositioned, offering efficiency and versatility in manufacturing processes.

Automotive Industry: HMCs are essential in automotive manufacturing, particularly for machining engine blocks, transmission housings, and other complex engine components. These parts need precise work on multiple sides, and the horizontal setup of HMCs makes it possible to machine them quickly and accurately. Gears and shafts, vital to the transmission system, also benefit from HMCs’ ability to meet tight tolerances, ensuring high performance and safety standards for vehicles, particularly when using high-speed machining techniques.

Aerospace Industry: The aerospace sector heavily relies on HMCs for the precision machining of critical components like landing gear, turbine blades, and other structural parts, often utilising rotary tables for enhanced efficiency. With materials such as titanium and Inconel being standard in aerospace manufacturing, the robustness of CNC machines allows for heavy-duty cuts while maintaining the fine tolerances required. The ability to machine multiple surfaces in one setup makes general purpose HMCs indispensable in producing the complex parts needed for aircraft.

Medical Device Manufacturing: When it comes to producing surgical instruments and medical implants, HMCs provide the high level of precision needed for intricate designs. Orthopedic implants, such as knee and hip replacements, require multi-axis machining to ensure they are shaped perfectly to fit the human body. The superior accuracy and consistency of general purpose HMC machines make them ideal for this kind of manufacturing, where even the slightest error can impact the quality of care for patients. The durability of CNC machines enables them to handle complex cuts while preserving precise tolerances.

Energy Sector: In the oil and gas industries, HMCs are used to create large, durable parts like valves, pumps, and components for drilling equipment. These parts are often subjected to harsh conditions, so they must be machined from tough materials, a task HMCs are well-equipped for. Similarly, in power generation, HMCs handle the precision machining of turbine components, ensuring the parts meet the high precision standards required for long-term efficiency and reliability.

Heavy Machinery: The production of parts for heavy machinery, such as those used in construction and agriculture, benefits greatly from the use of general purpose HMCs. Large components like those found in loaders, excavators, tractors, and harvesters require multi-sided machining that HMCs can handle efficiently. These machines can machine complex workpieces in fewer setups, ensuring the timely production of reliable, heavy-duty equipment components.

General Manufacturing: General purpose HMCs are highly valuable in general manufacturing, where they are used to produce complex parts like housings, brackets, and manifolds. Their ability to machine multiple surfaces without manual repositioning significantly boosts productivity, especially in batch production settings. With the integration of pallet changers and automated systems, HMCs allow manufacturers to streamline operations, maximising efficiency and reducing downtime.

Tool and Die Making: The tool and die industry benefits from the precision of HMCs, especially when creating moulds and dies for plastic injection moulding. These tools require extreme accuracy and fine surface finishes, both of which HMCs are known for delivering. The ability to perform complex, repetitive machining tasks makes them ideal for producing high-quality moulds that meet strict industry standards.

Military and Defence: General purpose HMCs are vital to the defence industry, where they are used to machine parts for weaponry and military vehicles. These components must be able to withstand extreme conditions and, therefore, need to be made from robust materials with absolute precision. HMCs provide the capability to meet the defence sector’s stringent requirements, producing high-quality parts with the durability and precision necessary for mission-critical equipment.

In all of these applications, the combination of versatility, precision, and efficiency makes general purpose HMCs an indispensable tool for industries requiring multi-surface machining and high production standards.

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download our comprehensive product brochure and learn how our products should support your needs.