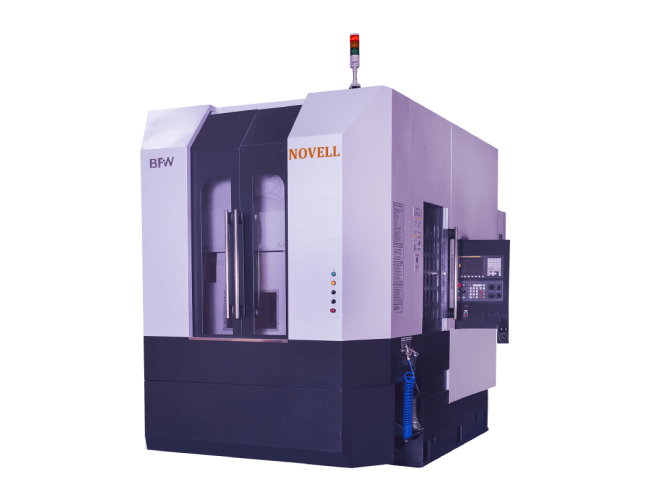

High-speed VMC series designed for rapid and precise machining operations.

Fixed-column VMC is ideal for industries requiring reliable and accurate machining processes.

Tailored Double Column VMC solutions for machining large-sized components.

Rotary Pallet VMC features that lower chip-to-chip time for high-volume production.

Multifunctional BFW CNC Vertical Milling Chandra series with 10 unique features.

Contact us online or join us at one of our events to explore potential partnerships and collaborations. Our custom solutions are manufactured using cutting-edge technologies and the latest methodologies.

Ready-made VMC machine and VMC machine solutions offer a comprehensive range of options for businesses seeking a cost-efficient approach to enhancing manufacturing capabilities without the need for custom manufacturing.

Vertical Machining Center (VMC) machines are a crucial asset in the manufacturing industry, offering advanced capabilities for precision machining processes. Understanding the basics of VMC machines is essential for maximising their potential across various industries.

VMC machines are vertically oriented milling machines equipped with a spindle that operates along the vertical axis. These CNC machines utilise cutting-edge technology to automate machining processes, enhancing productivity and machining accuracy. VMC machines commonly feature tool changers, high spindle speeds, and worktables for holding workpieces securely in place.

One of the primary advantages of VMC machines is their ability to perform a wide range of machining operations with high precision. These machines are capable of producing complex parts and components by leveraging multi-axis machining capabilities. The vertical orientation of the spindle allows for efficient chip removal and coolant application, ensuring optimal machining conditions.

Increased Precision and Accuracy

Versatility and Flexibility

Enhanced Productivity

Consistency and Repeatability

Reduced Downtime

Cost Efficiency

Improved Surface Finish

Complex Machining Capabilities

Operator Safety

Integration with Modern Technologies

Adaptability to Industry 4.0

Aerospace Industry

Automotive Industry

Medical Industry

Electronics Industry

Mould and Die Making

Energy Sector

Tool and Fixture Manufacturing

Prototyping and R&D

Defence and Military

By leveraging the capabilities of VMC machines, industries can achieve high precision, efficiency, and flexibility in their manufacturing processes, ensuring the production of high-quality parts and components.

VMC machines are revolutionising manufacturing processes with the integration of Computer Numerical Control (CNC) technology. The role of CNC in VMC machines is pivotal, as it allows for precise control over the machining operations, leading to enhanced productivity and superior machining accuracy.

CNC technology in VMC machines enables automated operation and programming, eliminating manual intervention and minimising human errors. Through CNC programming, operators can execute complex machining tasks with ease, ensuring consistent and repeatable results. The versatility of CNC in VMC machines allows for the creation of intricate parts and components with utmost accuracy.

CNC technology in VMC machines significantly boosts productivity by optimising machining processes and reducing setup times. With features like automatic tool changers and high spindle speeds, CNC-equipped VMC machines can swiftly switch between operations and achieve higher throughput. This efficiency translates to increased production capacity and quicker turnaround times for manufacturing operations.

Precision is a hallmark of VMC machines with CNC technology, as they can achieve tight tolerances and impeccable surface finishes. The integration of CNC ensures consistent part quality by minimising dimensional variations and enhancing overall accuracy. Additionally, CNC-controlled VMC machines excel in producing parts with complex geometries, thanks to their multi-axis machining capabilities and advanced programming functionalities.

VMC machines consist of several key components that play a crucial role in their operation and efficiency. Understanding these components is essential to grasp the functioning of VMC machines and optimise their performance in various industries.

The spindle in VMC machines serves as a pivotal component responsible for holding and rotating cutting tools during machining processes. It operates along the vertical axis, allowing for precise vertical movements essential for drilling, milling, and other machining operations. Spindle speed is a critical factor that influences the cutting performance and efficiency of VMC machines, impacting the quality of the machined parts.

Tools and tool changers are integral parts of VMC machines, enabling the automatic changing of cutting tools during machining operations. The efficiency of tool changers directly impacts the overall productivity of the machine, as quick tool changes reduce downtime and enhance machining efficiency. Proper tool selection and utilisation are essential in achieving optimal machining results and maintaining the longevity of the tools.

Rotary tables play a crucial role in enhancing the versatility and functionality of VMC machines by enabling multi-sided machining and complex part positioning. With the capability to rotate workpieces around multiple axes, rotary tables facilitate the machining of features at various angles, ensuring precise and intricate part production. They are particularly beneficial for industries requiring high-precision machining of components with irregular geometries.

Enhancing productivity and efficiency is a primary goal in VMC machining processes, as it directly impacts the profitability and competitiveness of manufacturing operations. Employing strategies to improve productivity and optimising the efficiency of BFW VMC machines can lead to significant advancements in machining performance and overall operational success.

To enhance productivity in VMC machines, manufacturers can implement various strategies such as optimising machining parameters, utilising advanced cutting tools, and streamlining the production workflow. Continuous monitoring of machine performance, preventive maintenance scheduling, and employee training programs also contribute to maximising productivity and reducing production costs.

BFW VMC machines offer advanced features and technologies aimed at optimising efficiency and output quality. Leveraging the capabilities of BFW VMC machines, operators can improve cycle times, reduce idle times, and enhance tool life through effective tool management. Additionally, integrating automation solutions and networking capabilities further boosts the efficiency and productivity of BFW VMC machines in modern manufacturing environments.

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon