Swift Nx

- Home

- Products

- 5 Axis Multi Process Machines

- Swift Nx

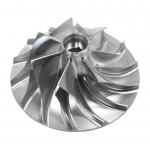

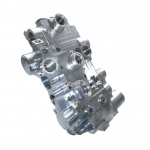

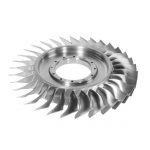

Swift Nx series designed for high precision, complex machining requirements. Machines built with robust FE optimized structure, high-speed motorized spindle. Integrated cradle-type rotary table gives precise indexing accuracy & high surface finish. Chain-type tool magazine, isolated from the working zone helps for higher productivity and better ergonomics.

BFW State-of-the-art five axes platforms, innovative designs as an Import substitute to meet advanced manufacturing requirements.

Swift Nx is extensively applied to the industries of aerospace, automotive, medical, energy, and further more…

Brand Story

Simultaneous fulfillment of high productivity & more reliability in the manufacturing setup. Known as a profit-making partner in your shopfloor.

- Standard Features

- Unique Features

- Optional Features

- Precise ball-screws for all linear axes

- Backlash & pitch error compensation

- Automatic centralised grease lubrication system

- Electronic counter-balance for the vertical axis

- Energy saving function

- Basic coolant system – Dual Conveyor with bed wash & flood coolant

- Rigid tapping & retract function

- 3-tier signal tower lamp

- Coolant gun

- Tool life management

- Absolute encoder for all axes

- 15″ color Multi-Touch display

- Linear, circular & helical interpolation

- Machine alarm diagnostics

- Motorized spindle

- Siemens Sinumerik One with M dynamics

- Tool magazine – 32 tools (Chain type)

- Roller type guide-ways for all linear axes

- Air blast for spindle taper cleaning

- AC unit for electrical cabinet

- Machine lamp

- Operator door safety interlock

- Five axes are equipped with scales for linear axes & absolute encoders for rotary axes as a standard to ensure

precise complex 5-axis simultaneous machining on complex parts - High Torque built-in spindle speed 12,000 to 15,000 RPM

- The Gantry structure of the machine features high rigidity

- Tandem control/ Gantry drive for tilting axis

- High-pressure coolant through the spindle system

- Protect my machine to avoid collision

- Spindle probe

- Mist collector

- Cad model post processor

- Standard tool holders

- Laser system to measure tool offset & tool breakage NC 4

- Machine color as per customer requirement

- VCS – Volumetric Compensation System

Watch Swift Nx Live In Action!

Specifications

| Specification | Unit | Nx5 | Nx8 |

| Table | |||

| Table size | mm | ø 500 | ø800 |

| Job size (Max) Dia × Ht | mm*mm | ø 630*400 | ø1000*500 |

| Max safe load on the table | kg | 400 | 1000 |

| Distance from table top to Spindle face | mm | 100-700 | 125-725 |

| Distance from Table top to floor | mm | 1100 | 1110 |

| Traverse | |||

| X/Y/Z axes | mm | 700/795/600 | 1100/1100/600 |

| Feed rate | mm/mm | 1-20000 | 1-20000 |

| Rapid traverse X/ Y/ Z axes | m/min | 50 | 40 |

| Acceleration | m/s2 | 0.5 | 0.5 |

| A axis | rpm | 16 | 16 |

| C axis | rpm | 60 | 60 |

| Spindle | |||

| Type | Motorised | Motorised | |

| Power - Cont. | kW | 27.5(40) | 40 |

| Max Torque - Cont./ Int. | Np | 75/103(100/140) | 100/140 |

| Max speed - Cont./ Int. | rpm | 12000/15000 | 12000/15000 |

| Tool Interface | HSK A63 | HSK A63 | |

| Automatic Tool Changer | |||

| No of Tools - Std (Option 1, Option 2) | No | 32 (40, 60) | 32 (40, 60) |

| Max tool dia with all pockets full | mm | 75 | 75 |

| Max tool dia with adjacent pockets empty | mm | 125 | 125 |

| Maximum tool length | mm | 300 | 300 |

| Tool weight | kg | 8 | 8 |

| Chip to chip time (mm) as per ISO 10791 - 9 | sec | 7.5 | 8 |

| Accuracy as per ISO 230 - 2 | |||

| Linear axes | |||

| Positioning A | mm | 0.006 | 0.006 |

| Repeatability R | mm | 0.004 | 0.004 |

| A axis - Tilting Table | |||

| Positioning A | arc sec | 10 | 10 |

| Repeatability R | arc sec | 8 | 8 |

| C axis - Rotary Table | |||

| Positioning A | arc sec | 10 | 10 |

| Repeatability R | arc sec | 8 | 8 |

| CNC System | Simens Sinumerik One | Simens Sinmuerik One | |

| Installation Data | |||

| Basic weight of machine | kg | ~16,000 | ~18,000 |

| Floor Area for Std. Machine W × D × H | mm | 3260*4550*4300 | 4070*5100*4480 |

| Total connected load | kVA | ~60 | ~75 |

| Compressed air | bar | 6 | 6 |

| Power supply | 415 V ± 10 % AC, 50 ± 2 % Hz, 3 phase | 415 V ± 10 % AC, 50 ± 2 % Hz, 3 phase | |

Applications

Have Any Question?

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Follow us on

PRODUCTS

RESOURCES

BFW UPDATES

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Get Quote

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download the brochure

Download our comprehensive product brochure and learn how our products should support your needs.