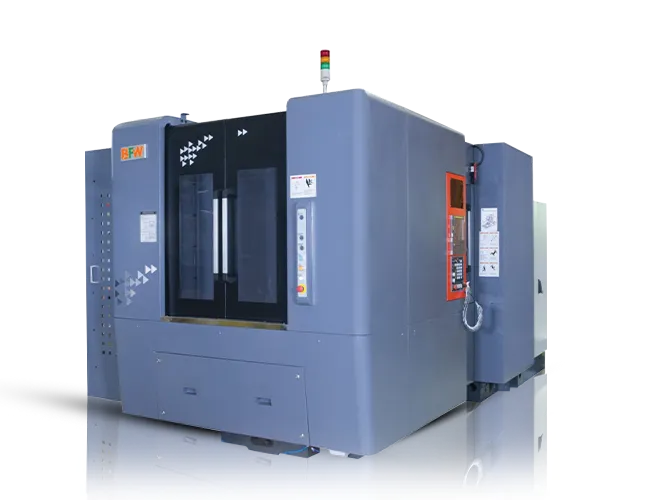

High Performance HMC

Excellent precision with the use of high-precision components and thermo-friendly features.

General Purpose HMC

Decades of experience to design Prima Pro HMC with next level performance and productivity.

Two Way HMC

The finest product built with decades of research in machine tool manufacturing.

Non APC HMC For Machining Lines

The fast, flexible, and compact MCR series are loaded with many advantages.

- 5.0

- Recommended by leading organizations

Join our global network of over 68,000+ machine installations

Contact us online or join us at one of our events to explore potential partnerships and collaborations. Our custom solutions are manufactured using cutting-edge technologies and the latest methodologies.

Off-the-shelf HMC Machines and HMC Machine full form solutions , designed to be readily available without the need for custom manufacturing, catering to a wide range of situations and industries. These solutions provide efficient and versatile options for businesses seeking high-quality machining capabilities, enabling them to streamline operations and enhance productivity.

Horizontal Machining Centers (HMCs) have transformed modern manufacturing with their ability to perform complex machining tasks with precision and efficiency. With their horizontally oriented spindles and advanced automation features, HMCs are ideal for high-volume production, handling complex parts with ease. As industries like aerospace, automotive, and medical devices demand increasingly intricate components, HMCs offer the versatility and productivity needed to meet those challenges. This article explores the key components, benefits, and diverse applications of HMC machines in today’s manufacturing landscape.

What is an HMC machine?

An HMC, or Horizontal Machining Center, is a type of CNC (Computer Numerical Control) machine where the spindle is oriented horizontally, allowing for more efficient machining of larger or more complex parts. The horizontal orientation makes it ideal for operations where chips fall away from the workpiece naturally, reducing the need for cleaning during machining. HMCs typically come equipped with advanced features like automatic tool changers, pallet systems for continuous operation, and multi-axis capabilities, making them highly efficient for high-volume production and precise, complex machining tasks. These machines are commonly used in industries such as aerospace, automotive, and heavy equipment manufacturing.

Key components of an HMC machine

The key components of horizontal machining center machines include:

- Spindle: The spindle in an HMC is oriented horizontally and holds the cutting tool, allowing it to rotate and perform machining operations like milling, drilling, and tapping.

- Automatic Tool Changer (ATC): This system automatically switches tools during machining operations, increasing efficiency and reducing manual intervention, particularly for complex or multi-step processes.

- Pallet System: HMCs are often equipped with a dual-pallet system, which allows one workpiece to be machined while another is being loaded or unloaded, ensuring continuous operation and minimizing downtime.

- Worktable: The worktable holds the workpiece securely in place and moves along the X, Y, and Z axes to allow precise machining. It may also rotate for multi-axis machining in more advanced HMCs.

- Control Panel: This is the interface where operators program the CNC system, input machining instructions, and monitor the machine’s performance.

- Cooling and Chip Management System: HMCs often include advanced cooling and chip removal systems to prevent overheating and ensure smooth operation, particularly for high-volume machining.

- Enclosure: The machine is typically enclosed to protect operators from flying debris, contain coolant, and reduce noise, ensuring a safer working environment.

These components work together to make HMCs highly efficient, versatile, and ideal for precision machining in large-scale production environments.

Benefits of an HMC machine

- Increased Productivity: HMCs often feature a dual-pallet system, allowing for continuous machining as one part can be worked on while another is being set up, significantly reducing downtime and increasing overall production efficiency.

- Enhanced Chip Evacuation: The horizontal orientation of the spindle helps gravity to naturally remove chips away from the workpiece, preventing buildup, improving machining accuracy, and reducing the need for frequent cleaning.

- High Precision and Accuracy: HMCs are equipped with CNC controls and advanced automation, ensuring consistent, repeatable machining with tight tolerances. This is crucial in industries requiring precise part production, such as aerospace and automotive.

- Multi-Sided Machining: HMCs allow for multi-axis machining, enabling complex parts to be machined from multiple angles without needing to reposition the workpiece manually. This improves precision and reduces time spent on setups.

- Versatility: HMCs can handle a wide variety of materials, from soft metals like aluminum to harder metals like steel and titanium. They can also be used for a range of operations, including milling, drilling, and tapping.

- Reduced Operator Intervention: With automated tool changers and pallet systems, HMCs reduce the need for manual intervention, leading to lower labor costs and reduced human error.

Applications of HMC machines

The applications of Horizontal Machining Centers (HMCs) span across a variety of industries due to their precision, efficiency, and versatility. Here are some key areas where HMCs are commonly used:

- Aerospace: HMCs are used to manufacture high-precision parts such as engine components, turbine blades, and structural parts. Their ability to machine complex geometries with tight tolerances is crucial for safety and performance in aerospace applications.

- Automotive: HMCs are widely used in the production of engine blocks, transmission housings, and other critical automotive components. The multi-axis capability and high productivity of HMCs make them ideal for high-volume, precise production.

- Heavy Equipment and Machinery: In industries such as construction, mining, and agriculture, HMCs are employed to machine large, heavy-duty components like hydraulic cylinders, frames, and gears that require precise machining and durability.

- Medical Devices: The high precision and ability to machine intricate details make HMCs suitable for creating medical equipment, implants, and surgical instruments that must meet stringent quality standards and biocompatibility requirements.

- Energy Sector: HMCs are used in the manufacturing of components for the oil and gas, wind, and power generation industries. These machines can produce parts such as turbine housings, valves, and drilling equipment that must withstand extreme conditions.

- Tool and Die Manufacturing: HMCs are commonly used in producing molds, dies, and tooling components used in injection molding, stamping, and other manufacturing processes. Their ability to handle complex shapes and high volumes ensures the consistent production of quality tools.

- Defense and Military: HMCs are applied in the production of weapons systems, ammunition, and military equipment. These machines can manufacture high-strength parts with precise geometries, crucial for defense applications that demand reliability and durability.

- Custom Fabrication: HMCs are ideal for custom or prototype manufacturing where unique, complex parts are required. Their flexibility allows for efficient production of one-off or low-volume parts with intricate details.

These applications highlight the importance of HMCs in industries requiring precision, efficiency, and the ability to handle complex parts and large volumes.

Conclusion

HMC machines have become indispensable in industries requiring precision, high productivity, and the capability to handle complex, multi-sided machining. Their advanced features, such as automatic tool changers and pallet systems, make them ideal for both large-scale production and custom fabrication. As manufacturing demands continue to evolve, HMCs remain a critical solution for producing high-quality parts efficiently and reliably. Whether in aerospace, automotive, or beyond, the versatility and performance of HMCs ensure they will continue to shape the future of machining.

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Follow us on

PRODUCTS

RESOURCES

BFW UPDATES

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Get Quote

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon