PL6050R (Turnmill Centre) : | 1000 mm| 1500 mm | 2000 mm |

Brand Story

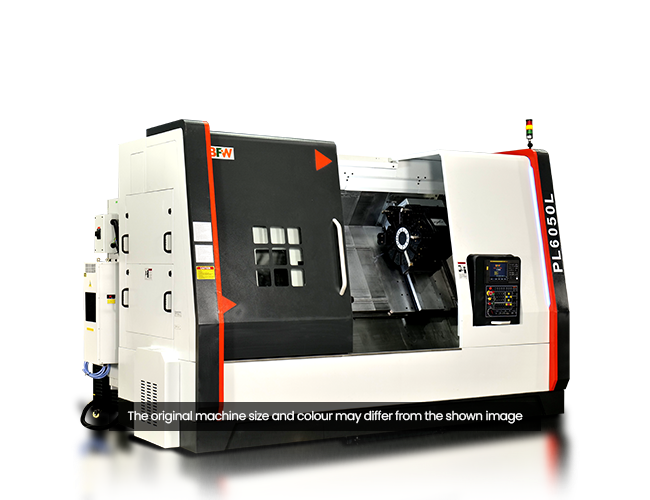

The PL6050 Series from BFW redefines heavy-duty CNC machining. Built with rugged precision, these machines are tailored for industries where size, strength, and accuracy matter. Whether it’s truck axles, marine crankshafts, or hard part turning, the PL6050L Turning Centre and PL6050R Turn-Mill Centre are designed to deliver relentless performance, round the clock.

Crafted with modular architecture, these machines blend traditional engineering reliability with smart innovations – enabling flexibility, uptime, and high productivity across demanding applications.

- Standard Features

- Unique Features

- Optional Features

- Turning Lengths: 1000 / 1500 / 2000 mm (for both Turning & Turn-Mill Centres)

- Swing Over Bed: Up to 700 mm | Between Centres: 560 mm

- 30° Slant Bed with 3-triangle compartment structure for rigidity

- Hand-Scraped Guideways with bell-curve oil grooves for superior lubrication

- Ground C3 Ballscrews with preloaded double nuts and angular contact bearings

- Headstock Options:

- 2 Belt Drive (up to 500 mm chuck, 12–1600 rpm)

- 2 Geared Drive (torque up to 1650 Nm with hydraulic gear shift)

- Turrets:

- Lathes: General purpose or crankshaft-type (32×32 mm tools)

- Turn-Mill: BMT 75 or VDI 50 live tool systems

- Tailstock: MT5 with 140 mm quill and revolving spindle

- CNC Systems: Fanuc OiTF Plus / Siemens 828D SL

- Chip Conveyors: Longitudinal and cross types (hinge or scraper)

- Operator Comfort: Swivel/sliding panels, full sheet metal enclosure

- Automation Ready: Gantry and robotic integration supported

- Triangular Bed Construction

- Bell-Curve Oil Grooves

- Live Turrets with BMT 75

- Geared Headstock with Hydraulic Gear Shift.

- Advanced Tailstock Design

Specifications

| SL.NO | DESCRIPTION | UNIT | PL6050 L | PL6050 R | ||||

|---|---|---|---|---|---|---|---|---|

| 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | |||

| 1 | Swing over Bed way Covers | mm | 700 | 700 | 685 | 715 | 700 | 685 |

| 2 | Swing between Centres | mm | 560 | 560 | ||||

| 3 | Maximum Turning Dia. on chuck | mm | 650 | - | ||||

| 3 | Maximum Turning Dia. BMT-75 disc | mm | - | 630 | ||||

| 4 | Maximum Turning Dia. VDI 50 disc | mm | - | 560 | ||||

| 5 | Maximum Turning Length from Chuck Face | mm | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 |

| 6 | Spindle Nose / Hole through Spindle | Type / mm | A2-11/108 (A2-11/140) | A2-11/108 (A2-11/140) | ||||

| 7 | Type of Drive | Type | Gear (Belt) | Gear Drive | ||||

| 8 | Spindle Motor Power | kW | 22/26 (30/37) | 22/26 (30/37) (28/33.6) | ||||

| 9 | Maximum Chuck Dia | mm | 400 (500) | 400 (500) | ||||

| 10 | Turret Make & Model | Type | BFW / Size 25 (GPM / Size 25) | GPM / Baruffaldi Size 25 | ||||

| 11 | Type of Turret | Type | Hydraulic (Servo Hydraulic) | Servo Hydraulic | ||||

| 12 | Type of Tool clamping system | Type | - | BMT 75 ( VDI 50) | ||||

| 13 | No. of Tool Station : Disc Size | Nos/mm | 12 / 520 A/F | 12 / 430 A/F (12; 420 pcd Axial disc) | ||||

| 14 | Turning Tool Shank / Boring Bar size | mm | 32 × 32 / 60 | 32 × 32 / 50 | ||||

| 15 | Max tool overhang- In-Line Live Head | mm | - | 85 for in Line Live Head / 85 for Right angle live head | ||||

| 16 | Live Motor a. Fanuc Spindle motor | - | 5.5 kW, 4000 rpm (Fanuc)/ 7 kW 4000 RPM (Siemens) | |||||

| 17 | Tailstock Taper size | MT | MT5 | MT5 | ||||

| 18 | Quill Dia / Stroke | mm/mm | Dia 140 × 125 | Dia 140 × 125 | ||||

| 19 | Movement on Bed | Type | Hyd. Linking (Servo by lead screw) | Hyd. Linking (Servo by lead screw) | ||||

| 20 | Steady Rest Biggest (Max. Clamping range) | mm | 80 – 390 | 80 – 390 | ||||

| 21 | Machine Basic Weight | Kg | 9000 | 9500 | 10500 | 9000 | 9500 | 10500 |

| 22 | Machine Length × Width × Height | Mtr × Mtr × Mtr | 4.15 × 2.5 × 2.7 | 4.65 × 2.5 × 2.7 | 5.2 × 2.5 × 2.7 | 4.15 × 2.5 × 2.7 | 4.65 × 2.5 × 2.7 | 5.2 × 2.5 × 2.7 |

| 23 | Total Connected Power | kVA | 60 – 80 kVA, 415V, 3ph, 50Hz | 60 – 80 kVA, 415V, 3ph, 50Hz | ||||

Have Any Question?

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Follow us on

PRODUCTS

RESOURCES

BFW UPDATES

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Get Quote

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download the brochure

Download our comprehensive product brochure and learn how our products should support your needs.