FAQ

VMCs are used for precision machining components across industries like automotive, aerospace, medical devices, die & mold making, and electronics. They perform milling, drilling, tapping, and multi-axis operations efficiently.

A VMC uses vertically oriented cutting tool with relative motion between the workpiece and the tool. The CNC system controls movement, ensuring precise and repeatable operations.

- Higher accuracy and precision

- Faster production cycles with automation

- Consistent quality across multiple parts

- Reduced manual intervention and improved safety

- Easier integration with automation and monitoring systems

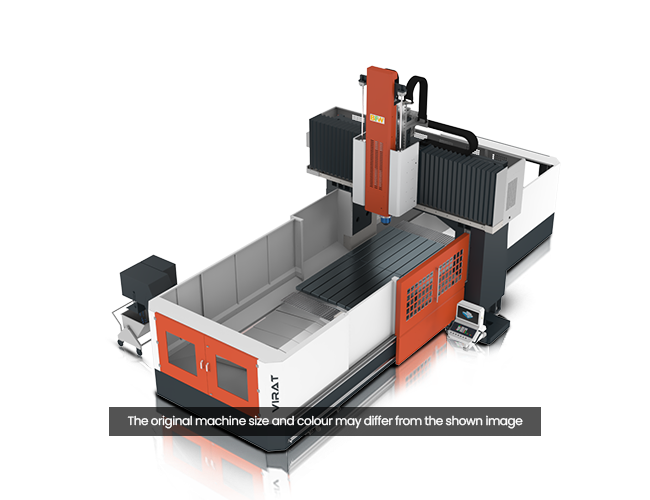

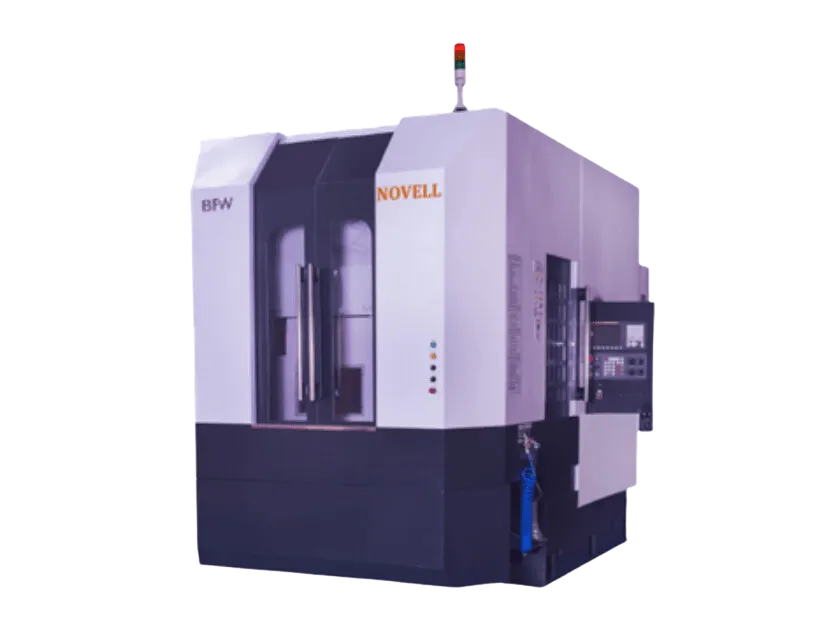

VMC is a type of CNC milling machine with a vertically oriented spindle and ATC. While all VMCs are CNC machines, not all CNC milling machines are VMCs—they may have horizontal spindles (HMC) or other configurations.

BFW’s BMV 45+ or similar compact VMCs are ideal for small batch production, offering flexibility, high precision, and faster setup times.

VMC prices vary depending on model, specifications, and features. BFW provides customized solutions—contact their sales team for a quote tailored to your requirements.

BFW VMCs achieve high accuracy, typically up to ±0.02 mm, depending on the model and operating conditions.

Regular maintenance includes:

- Cleaning of spindles and guideways

- Checking lubrication oil level

- Checking air quality and pressure setting as required by respective machines.

- Checking coolant levels, filters & coolant Quality

- Tool inspection and calibration

- Regular checking of messages & alarms on the CNC systems (as per the preventive chart checklist)

BFW provides guidelines and support for all maintenance procedures.

Yes. BFW VMCs can integrate with robotic arms, pallet changers, and other automation solutions to increase throughput, reduce manual labor, and improve consistency.

- VMC (Vertical Machining Center): The Spindle is vertical; generally used for the singe face machining.

- HMC (Horizontal Machining Center): The Spindle is horizontal; generally used for multi-faced machining.

BFW is among the leading VMC manufacturers in India, known for reliability, precision, and post-sales support. Other prominent manufacturers include HMT, Ace Micromatic, LMW and Jyoti CNC.

VMCs can produce:

- Engine parts, brackets, and chassis components

- Aerospace housing and structural parts

- Surgical instruments and implants

- Dies, moulds, and tooling components

- Small, high-precision electronic parts

BFW VMCs are compatible with standard CNC programming languages (G-code/M-code) and software like Mastercam, Siemens NX, CATIA, and Fusion 360 for toolpath generation.

Consider:

- Workpiece size and material

- Required accuracy and surface finish

- Production volume (small batch vs. mass production)

- Automation and integration needs

BFW’s team provides consultation to select the ideal VMC for your manufacturing requirements.

Yes. BFW offers operator training, maintenance guidance, and technical support to ensure customers get the best performance and longevity from their VMC machines.