BFW Trending

Company and Industry Insights

Learn more about our projects and customers, events and conferences, BFW organization updates, and the latest product news by visiting our knowledge zone.

Tailored solutions for machining large-sized components for Aerospace & Energy spaces.

Contact us online or join us at one of our events to explore potential partnerships and collaborations. Our custom solutions are manufactured using cutting-edge technologies and the latest methodologies.

Ready-made VMC machine and VMC machine solutions offer a comprehensive range of options for businesses seeking a cost-efficient approach to enhancing manufacturing capabilities without the need for custom manufacturing.

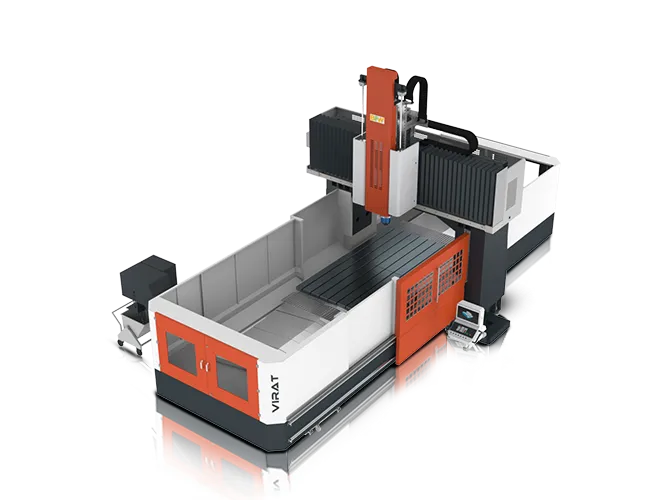

In the fast-paced world of modern manufacturing, staying ahead means leveraging the right tools for the job. The Double Column VMC (Vertical Machining Center) offers a compelling solution for companies looking to enhance precision and efficiency in their production processes. Known for its robust design and exceptional performance, this machine is becoming indispensable in industries where the stakes are high. Find out more about the double column VMC below.

A Double Column VMC is a high-performance milling machine designed for heavy-duty machining tasks. It features two robust vertical columns that provide exceptional stability and precision, making it ideal for machining large and complex parts. These machines are widely used in industries such as aerospace and automotive, where the accuracy and quality of components are critical. The double column design minimizes vibration, enabling high precision even in demanding operations, while advanced features like automatic tool changers and high-speed spindles enhance productivity and efficiency

A Double column VMC offers several significant advantages:

Superior Rigidity and Stability: The double column design of these machines features two vertical supports, which significantly enhances their structural rigidity compared to single-column machines. This design minimizes deflection and vibration during machining, leading to more accurate cuts. This stability is particularly important when working with large or heavy workpieces, as even slight movements can lead to errors in the final product.

High Accuracy: Double Column VMCs are known for their ability to maintain high levels of precision, even in complex and large-scale machining operations. The reduced vibration and increased rigidity allow these machines to produce parts with very tight tolerances. This is essential in industries like aerospace and automotive, where even minor deviations can result in performance issues or safety risks.

Increased Productivity: These machines are designed with productivity in mind. Features like automatic tool changers, which quickly switch between different tools during a machining process, and high-speed spindles, which reduce the time spent on each operation, contribute to faster production cycles. This allows manufacturers to produce more parts in less time, enhancing overall efficiency and reducing costs.

Versatility: Double Column VMCs are not limited to a single type of machining operation. They can perform a variety of processes, including milling, drilling, and tapping, making them highly versatile. This versatility allows manufacturers to use the same machine for different tasks, which can be particularly beneficial in job shops or manufacturing environments that require flexibility.

Durability: Built for heavy-duty operations, these machines are designed to withstand the demands of continuous use in tough environments. The robust construction ensures that they can maintain precision and performance over long periods, even when subjected to the stresses of machining large or difficult-to-machine materials. This durability not only extends the life of the machine but also reduces maintenance costs and downtime

Double Column VMCs are utilized across various industries due to their ability to handle large, heavy, and complex workpieces with high precision. Here are some key applications:

Aerospace Industry: Double Column VMCs are used to machine large aircraft components such as wing spars, fuselage parts, and landing gear components. The precision and stability offered by these machines are critical for producing parts that meet the stringent safety and performance standards required in aerospace manufacturing.

Automotive Industry: In automotive manufacturing, Double Column VMCs are employed to produce engine blocks, transmission housings, chassis components, and other large parts. The machines’ ability to handle heavy-duty materials and maintain tight tolerances makes them ideal for high-volume production environments.

Mold and Die Making: These machines are extensively used in the mold and die industry to create large molds for injection molding, as well as dies for stamping and forging processes. The accuracy and versatility of Double Column VMCs allow manufacturers to produce intricate mold cavities and cores efficiently.

Energy Sector: Double Column VMCs are used to machine large components for power generation equipment, such as turbine housings and wind turbine components. The ability to handle large workpieces with precision is crucial in ensuring the performance and reliability of energy sector equipment.

Shipbuilding: In shipbuilding, Double Column VMCs are employed to machine large parts of ship structures, such as bulkheads, engine parts, and other critical components. The machines’ capacity to work on oversized parts ensures that the components are manufactured with the necessary precision and durability

General Engineering and Heavy Equipment Manufacturing: Double Column VMCs are also used in the production of heavy machinery and construction equipment, where large and robust components are required. Their ability to perform various machining tasks on large workpieces makes them a versatile tool in these industries.

These applications highlight the versatility and importance of Double Column VMCs in industries that demand precision, reliability, and the ability to work with large and heavy materials.

Learn more about our projects and customers, events and conferences, BFW organization updates, and the latest product news by visiting our knowledge zone.

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon