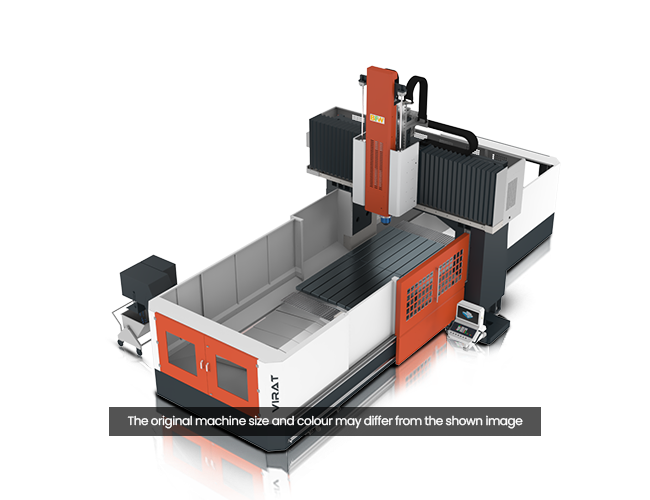

“Tailor made solutions for machining large sized components for Aerospace & Energy segments”

Brand Story

BFWs Virat Double Column VMC is “Majestic; brilliant”, Very Big or Giant. Captivator of enhanced shop floor productivity.

- Standard Features

- Unique Features

- Optional Features

- BT 50 spindle – 6000 rpm

- AC servo drives

- Hardened & ground LM roller guideways for X ,Y & Z axis

- Hardened & ground ball-screws for all the 3 axes

- In-line spindle

- Coolant gun

- Air gun

- Air blast for spindle taper cleaning

- Air curtain for spindle

- Centralized lubrication system

- Hydraulic counter balance for the vertical axis

- Feedback through absolute encoder

- Rigid taping facility

- Ring coolant

- Telescopic covers, bellows & splash guards

- Instruction manuals

- Machine lamp

- Leveling & foundation kit

- Mobile MPG

- Standard coolant system with chip tray

- Coil conveyor on either side of the bed

- Maintenance toolkit

- Cutting zone completely isolated from the machine elements and the operator

- Heavy-duty cutting capability

- Compact foot print

- Single lift machine for Virat 1020

- Flexible machining Center

- Heavily ribbed Base, Column for more rigidity

- ATC for BT 50 tool holder

- Coolant through system

- Spindle chiller

- 30/40/60 tools magazine

- Height block

- Linear glass scale for X, Y & Z axes

- Full enclosure splash guard

- Chip conveyor with chip trolley

- Dual stage high/low planetary gear box

- Oil skimmer

- AC for electrical cabinet

- Voltage stabilizer

- Spindle mounted probe

- 90 deg automatic indexing head with auto transfer

- Manually head with parking station

- Auto workpiece measurement

- 4-axis rotary table

Watch VIRAT Live In Action!

Specifications

| Technical Specification | ||||||||||||||||

| Specifications | Unit | VIRAT- 1000 | VIRAT- 1500 | VIRAT- 2000 | VIRAT- 3000 | |||||||||||

| MODEL | VIRAT- | 1020 | 1520 | 1530 | 1540 | 2030 | 2440 | 3040 | ||||||||

| X – Axis Travel (Table longitudinal) | mm | 2000 | 2000 | 3000 | 4000 | 3000 | 4000 | 4000 | ||||||||

| Y – Axis Travel (Saddle Transverse) | mm | 1200 | 1700 | 1700 | 1700 | 2400 | 2600 | 3400 | ||||||||

| Z – Axis Travel (Ram Vertical) | mm | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | ||||||||

| Spindle nose face to table top | mm | 150~950 | 200~1200 | 200~1200 | 200~1200 | 350~1350 | ||||||||||

| Increased daylight with Height block (option) | mm | 200 | 300 | 300 | 300 | 350 | ||||||||||

| Distance from Floor to table | mm | ~820 | ~870 | ~1020 | ~1020 | ~1020 | ||||||||||

| Distance between Column | mm | ~1280 | ~1780 | ~2480 | ~2680 | ~3480 | ||||||||||

| Table | ||||||||||||||||

| Table size | mm | 1000X2200 | 1500X2200 | 1500X3200 | 1500X4200 | 2000X3200 | 2400x4200 | 3000X4200 | ||||||||

| Table working area | mm | 1000X2000 | 1500X2000 | 1500X3000 | 1500X4000 | 2000X3000 | 2400x4000 | 3000X4000 | ||||||||

| T - Slot (No. / Size / Pitch) | mm | 7x22x150 | 9x22x160 | 9x22x210 | 11x22x210 | 17x28x250 | ||||||||||

| Max. Load on table Std. | Kgs | 4000 | 6000 | 8000 | 10000 | 10000 | 12000 | 16000 | ||||||||

| Axes | ||||||||||||||||

| Rapid traverse - X/Y/Z - Std. | m/min | 20/20/15 | 18/20/15 | 15/20/15 | 12/20/15 | 15/15/12 | 12/15/12 | 10/10/10 | ||||||||

| Feed rate | mm/min | 1 – 10000 | 1 – 10000 | 1 – 10000 | 1 – 8000 | 1 – 8000 | ||||||||||

| Spindle Taper, Power- Torque & Speed Details | ||||||||||||||||

| Spindle : Inline Drive: STD ( *Coolant through with Belt driven only) | ||||||||||||||||

| Spindle Taper | Type | BT50 | BT50 | BT50 | BT50 | |||||||||||

| Fanuc Power-Cont/15min(Torque) | Kw/Nm | 15/18.5 Kw(143/235Nm) | 15/18.5 Kw(286/353Nm) | 18.5/22 Kw(310/525Nm) | 22/30 Kw(365/498Nm) | |||||||||||

| Mitsubishi Power-Cont/30min(Torque) | Kw/Nm | 15/18.5 Kw(143/236Nm) | 18.5/22 Kw(310/442Nm) | 18.5/22 Kw(310/442Nm) | 18.5/22 Kw(310/442Nm) | |||||||||||

| Siemens Power-Cont./ S6/60%(Torque) | Kw/Nm | 17/25.5 Kw(183/274Nm) | 22/26 Kw(248/300Nm) | 22/26 Kw(248/300Nm) | 22/26 Kw(248/300Nm) | |||||||||||

| Speed : STD | RPM | 6000 | 6000 | 6000 | 6000 | |||||||||||

| Spindle : Inline Gear Box Drive 1:4 Gear Ratio :Option | ||||||||||||||||

| Fanuc Power-Cont/30min(Torque) | Kw | 22/26Kw(560/664Nm) | 22/26Kw(560/664Nm) | 22/26Kw(560/664Nm) | 22/26Kw(560/664Nm) | |||||||||||

| Mitsubishi Power-Cont/30min(Torque) | Kw | 22/26Kw(560/664Nm) | 22/26Kw(560/664Nm) | 22/26Kw(560/664Nm) | 22/26Kw(560/664Nm) | |||||||||||

| Siemens Power-Cont/30min(Torque) | Kw | 22/26Kw(560/688Nm) | 22/26Kw(560/688Nm) | 22/26Kw(560/688Nm) | 22/26Kw(560/688Nm) | |||||||||||

| Speed : STD (Chiller for gearbox) | RPM | 6000 | 6000 | 6000 | 6000 | |||||||||||

| Automatic Tool changer : Twin Arm | ||||||||||||||||

| Tool change system | Type | Arm type | Arm type | Arm type | Arm type | |||||||||||

| Tool storage capacity - Std. / Opt. | Nos. | 20(30 with Height block) | 20(30/40) | 20(30/40/60) | 40 (60) | 20(30/40/60) | ||||||||||

| Max tool dia with all pockets full | mm | 125 | 125 | 125 | 125 | |||||||||||

| Max tool dia with adjacent pockets empty | mm | 220 | 220 (200) | 220 (200) | 220 (200) | |||||||||||

| Max tool length | mm | 350 | 350 | 350 | 350 | |||||||||||

| Pull Stud | Type | MAS 403 P50T-1 | MAS 403 P50T-1 | MAS 403 P50T-1 | MAS 403 P50T-1 | |||||||||||

| Accuracy as per ISO-230-2 (Full Stroke) | ||||||||||||||||

| Positioning Accuracy( without scale/with scale) | mm | 0.020/0.010 | 0.020/0.010 | 0.025/0.015 | 0.035/0.020 | 0.025/0.015 | 0.035/0.020 | 0.020 | ||||||||

| Repeatability Accuracy ( without scale/with scale) | mm | 0.015/0.008 | 0.015/0.008 | 0.020/0.012 | 0.025/0.015 | 0.020/0.012 | 0.025/0.015 | 0.015 | ||||||||

| Installation Data | ||||||||||||||||

| Floor Space (W x D) | mmxmm | ~4900 x 6900 | ~5500 x 6900 | ~5500 x 9900 | ~5500 x 13000 | ~6200 x 9900 | ~6800x13000 | ~8000 x 14000 | ||||||||

| Machine height (H) | mm | ~4400 | ~5200 | ~5200 | ~5200 | ~5500 | ~5500 | ~6000 | ||||||||

| Basic machine weight(Approximate) | kgs | ~20000 | ~24000 | ~28000 | ~32000 | ~36000 | ~40000 | ~50000 | ||||||||

| NOTE : values within parentheses are subject to change. | ||||||||||||||||

Applications

Have Any Question?

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Follow us on

PRODUCTS

RESOURCES

BFW UPDATES

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Get Quote

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download the brochure

Download our comprehensive product brochure and learn how our products should support your needs.