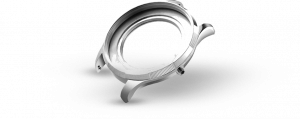

Omega Duo Series

True to it’s name, OMEGA represents the family of High Speed Machining Centers, which are an ultimate combination of Productivity and Precision. They are specially crafted to meet the dynamically rising global market demands across various industry segments from Electronics to Automotive to Aerospace to Defence.

Brand Story

True to it’s name, OMEGA represents the family of High Speed Machining Centers, which are an ultimate combination of Productivity and Precision. They are specially crafted to meet the dynamically rising global market demands across various industry segments from Electronics to Automotive to Aerospace to Defence.

- Standard Features

- Unique Features

- Optional Features

High productive machine with rapid rates up to 54m/min, minimum tool change time of 1.3 sec & spindle speeds up to 24,000rpm.

Wide range of products in BBT30 and BBT40 (HSK A63) variants with axes strokes going upto 1000x600mm, making the Omega machines suitable for many Electronics & EV parts.

Omega Penta brings in 5 axis continuous machining capability to the Omega range.

Omega Duo, with it’s innovative configuration of independent Z axis, helps achieve unmatched productivity combined with savings in floor space and energy consumption.

Specifications

| OMEGA DUO | ||

| 30 | 40L | |

| Traverse & Table | ||

| X Axis (mm) | 700 | 800 |

| Y Axis (mm) | 450 | 600 |

| Z Axis (mm) | 330 | 600 |

| Spindle face to table top - Min./Max.(mm) | 150/480 (300/630) | 130/730 |

| Table Size(mm x mm) | 900 x 420 | 1200 x 600 |

| Max Load (kg) | 300 | 400 |

| Spindle | ||

| Taper | BBT 30 | BBT 40 |

| Spindle Power (kW) Cont /int | 3.7/5.5/7.5 | 7.5/11/15 |

| Torque (Nm) | 23.5/35.5/44 | 47.7/70/95.5 |

| Maximum Speed (opt) (RPM) | 12000 (20,000) | 10000 |

| Axis | ||

| X/Y/Z Rapid Traverse (m/min) | 48/48/48 | 36/36/36 |

| X/Y/Z Max cutting feed rate (mm/min) | 20 | 20 |

| Tool Magazine | ||

| Type | Direct Pickup | Twin Arm |

| Max Pockets of Tool Magazine | 21 | 24 |

| Max tool Diameter (mm) | 80 | 80/125 |

| Max tool weight (kg) | 3 | 6 |

| Max Tool length (mm) | 200 | 250 |

| Chip to Chip time (Seconds) | 2.2 | 3.9 |

| Accessories | ||

| Coolant gun and air gun | Yes | Yes |

| 3 Tier lamp | Yes | Yes |

| Lamella cover for Z axis | Yes | Yes |

| Auto front door | Optional | Optional |

| 4th axis readiness with drive+motor | Optional | Optional |

| Coolant through Spindle (Optional) | 16 Bar | 16 Bar |

| CNC System | ||

| CNC System | BFW-SYNTEC | Mitsubishi-M80 |

| Accuracy | ||

| Positioning (mm) | 0.008 | 0.008 |

| Repeatibility (mm) | 0.006 | 0.006 |

Applications

Have Any Question?

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Follow us on

PRODUCTS

RESOURCES

BFW UPDATES

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Get Quote

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download the brochure

Download our comprehensive product brochure and learn how our products should support your needs.