BFW Trending

Company and industry insights

Learn more about our projects and customers, events and conferences, BFW organization updates, and the latest product news by visiting our knowledge zone.

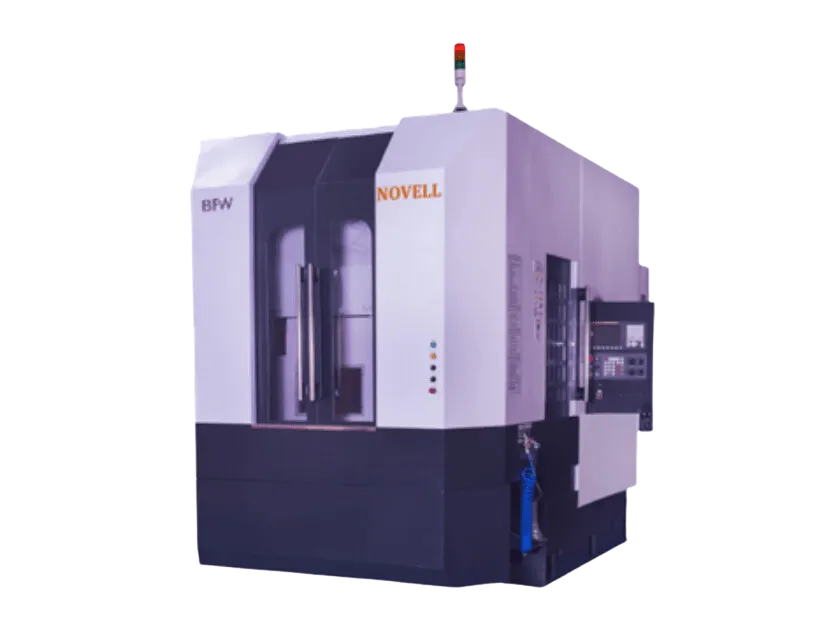

Built with a Rigid cast iron structure and lower chip-to-chip time for high-volume production.

Contact us online or join us at one of our events to explore potential partnerships and collaborations. Our custom solutions are manufactured using cutting-edge technologies and the latest methodologies.

Ready-made VMC machine and VMC machine solutions offer a comprehensive range of options for businesses seeking a cost-efficient approach to enhancing manufacturing capabilities without the need for custom manufacturing.

Imagine a machining system that could seamlessly eliminate downtime while driving efficiency to new heights. The Rotary Pallet VMCs (Vertical Machining Center) engineered to do just that, offering a sophisticated solution that keeps production lines in constant motion. If you’re looking to explore a technology that could significantly enhance your manufacturing operations, this could be the game-changer you’ve been waiting for.

A Rotary Pallet VMC (Vertical Machining Center) is a type of milling machine designed to maximise productivity by incorporating a rotary pallet system. This system allows for continuous machining operations by enabling workpieces to be loaded and unloaded on different pallets without stopping the machine. While one workpiece is being machined, another can be set up on a different pallet, which then rotates into position for machining as soon as the current operation is complete. This seamless transition reduces downtime, enhances efficiency, and is especially valuable in high-volume production environments.

Rotary pallet VMCs are used for many of their benefits. Here we will focus on the main benefits:

Reduced Downtime: The rotary pallet system allows for continuous machining operations by enabling workpieces to be loaded and unloaded without stopping the machine, significantly minimising idle time and increasing overall equipment efficiency (OEE).

Increased Productivity: By allowing one workpiece to be set up while another is being machined, the system maximises throughput and overall production efficiency, which is particularly beneficial in high-demand manufacturing environments.

Enhanced Workflow Flexibility: The ability to quickly switch between different workpieces or setups without interrupting the machining process increases operational flexibility and responsiveness to production demands, making it easier to manage varying production schedules.

Consistent Production Cycles: Continuous operation capabilities result in more consistent production cycles, which can improve delivery times and overall production scheduling, ensuring that deadlines are met more reliably.

Improved Efficiency in High-Volume Production: Particularly valuable in high-volume manufacturing, the system optimises machine utilisation and ensures that production processes run as efficiently as possible, which can be crucial for maintaining competitiveness in fast-paced industries.

Rotary Pallet VMCs are highly versatile and find applications across various industries due to their ability to handle continuous, high-efficiency machining operations. Here are some key applications:

Automotive Industry: In the automotive sector, Rotary Pallet VMCs are used for the mass production of components such as engine blocks, transmission cases, and other critical parts. The ability to switch between pallets without stopping the machine enables manufacturers to maintain high production rates and meet the demands of large-scale automotive manufacturing.

Aerospace Industry: Aerospace manufacturing requires high precision and efficiency, especially when producing complex components like turbine blades, structural parts, and landing gear components. Rotary Pallet VMCs are ideal for this sector as they allow for continuous machining of these intricate parts, ensuring consistent quality while reducing production time.

Medical Device Manufacturing: The medical industry demands precise machining for the production of components like surgical instruments, implants, and prosthetic parts. Rotary Pallet VMCs are used to maintain high productivity while ensuring the accuracy required for these critical applications. The ability to set up new workpieces while machining others is particularly beneficial in meeting the stringent timelines often required in medical device production.

Heavy Equipment and Machinery Manufacturing: In the production of large machinery and heavy equipment, such as construction machinery components or industrial equipment parts, Rotary Pallet VMCs offer the capability to handle heavy-duty machining tasks efficiently. Their continuous operation is crucial in environments where large parts need to be produced quickly and with precision.

General Manufacturing and Job Shops: In job shops or general manufacturing environments, where a variety of parts and components are produced, Rotary Pallet VMCs offer the flexibility to switch between different jobs without interrupting the production process. This versatility makes them ideal for operations that need to adapt quickly to different customer requirements and production schedules.

Learn more about our projects and customers, events and conferences, BFW organization updates, and the latest product news by visiting our knowledge zone.

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon