Orion Fx

- Home

- Products

- 5 Axis Multi Process Machines

- Orion Fx

FX series has been developed on the proven platform of ORION series Horizontal Machining Centers.

Innovated to meet the configuration for the Balance of precision and speed for complex precision parts machining and import substitution. Introduced to meet the demand for World-class HMCs for the Indian and global market.

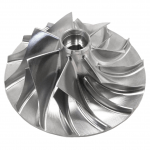

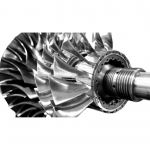

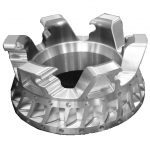

ORION Fx series is extensively applied to the industries of aerospace, automotive, medical, energy, and further more.

Brand Story

Fx series are developed for high performance manufacturing solutions & guarantees double in your returns

- Standard Features

- Unique Features

- Optional Features

- HSK spindle taper

- Motorized (Integral) spindle

- Spindle cooling B & C axis cooling system

- AC servo drives for all axis

- ú Ball-screw cooling system

- Continuous Direct Drive rotary table (0.001 deg x 360,000)

- Continuous swivel axis 0.001 deg

- Pneumatic counterbalance for vertical axis

- Single sheet covers for Z-axis/ Telescopic cover

- Automatic centralized oil lubrication system

- Stainless Steel Lamella covers for X&Y axis and Stainless Steel Single sheet cover for Z axis.

- Air blast for spindle taper cleaning

- Slat Chip conveyor inside the machine, in the cutting area

- 60 tools, servo-driven tool magazine & tool changer

- Overhead shower wash

- Basic coolant system with Scraper chip conveyor with drum filter

- High-pressure coolant through spindle system 40 bar with paper band filtration system

- Hydraulic power pack with air blast oil cooler

- 10.4″ color LCD display

- 3-tier signal lamp, machine lamp

- Machine alarm diagnostics

- Ballscrew core for cooling all three axis

- Simultaneous 5 axis

- Thermally symmetric structure

- Servo driven – APC, ATC & Tool Magazine, Index Table for higher reliability & Productivity

- High speed spindle

- Extensive series range

- Modular design

- Indigenous developed technology

- Automatic pallet changer (Servo-driven, Rotary type)

- Milling and Turning table, Dia 800, 500 rpm for Fx8000

- Automation and SMED compatible

- Tool kit for checking & correcting kinematic precision

- Automatic centralized grease lubrication system

- Cad model post processor

- Milling and Turning table, Dia 630, 700 rpm for Fx8000

- Mist collector

- Machine Collision monitoring

- 15″ color LCD Display

- IIoT 4.0

- Customer-specified machine colors

- Coolant chiller

- Visiport

- High torque spindle for Fx8000 & Fx10000]High-pressure coolant thru spindle system 60 bar

- Hydraulic connections through pallets with auto couplers (Fx5500 & Fx8000)

- ATC side tool breakage sensor

- Part probing

- Laser measuring system for tool offset & tool breakage

Watch ORION FX Live In Action!

Specifications

| Specifications | Unit | Fx5500 | Fx8000 | Fx10000 |

| Axis | ||||

| X axis | mm | 800 | 1250 | 1600 |

| Y axis (Table) | mm | 1000 | 1250 | 1400 |

| Z axis (Spindle) | mm | 800 | 1000 | 1250 |

| Work volume XYZ | 3 m | 0.64 | 1.25 | 2.5 |

| Rapid traverse | m/ min | 60 | 40 | 40 |

| Acceleration | 2 m/ S | 6 | 4 | 4 |

| Table | ||||

| Rotary table - Direct Drive | posn | 360,000 x 0.001deg | 360,000 x 0.001deg | 360,000 x 0.001deg |

| Table speed | rpm | 40 | 20 | 10 |

| Pallet size | mm | 500 x 500 | 630 x 630 (800 x 800) | 1000 x 1000 |

| Load capacity | kg | 700 | 1500 | 3000 |

| Max. Job swing dia x swing height | mm | 800 x 1000 | 1250 x 1200 | 1600 x 1400 |

| Spindle | ||||

| Spindle taper std. | HSK A63 | HSK A100 | HSK A100 | |

| Spindle power Ed40% std. | kW | 28 | 63 | 63 |

| Spindle speed std. | Nm | 12000 | 8000 | 8000 |

| Max spindle torque std. | Nm | 105 | 470 | 470 |

| Spindle taper (high speed opt) | - | HSK A63 | HSK A63 | |

| Spindle power ED40% (high speed opt) | kW | - | 28 | 28 |

| Spindle speed (high speed opt.) | rpm | - | 12000 | 12000 |

| Max spindle torque (high speed opt) | Nm | - | 105 | 105 |

| Swivelling Milling Head | ||||

| Rotating speed Cont./ 50% ED | mm | 10 | 10 | 10 |

| Axis torque | mm | 3,000 | 5,000 | 5,000 |

| Resolution | deg | 0.001 | 0.001 | 0.001 |

| Automatic tool changer | ||||

| Number of tools std | 60 | 60 | 60 | |

| Number of tools opt | 80 | 80-120 | 80-120 | |

| Max tool diameter all places | mm | 80 | 125 | 125 |

| Max tool diameter max | mm | 165 | 250 (315) | 250 (315) |

| Max tool length | mm | 430 | 600 | 600 |

| Max tool weight | kg | 12 | 30 | 30 |

| Chip to chip time (min) | s | 4 | 7.5 | 8.7 |

| Pallet changer | ||||

| Type | 180 deg swing type | |||

| Pallet change time | s | 10 | 25 | 60 |

| Accuracy as per ISO 230-2 | ||||

| Positioning A - with Linear scale | mm | 0.008 | 0.008 | 0.009 |

| Repeatability R - with Linear scale | mm | 0.005 | 0.005 | 0.007 |

| B & C axis index accuracy | arcsec | 10 | 10 | 12 |

| Machine Installation Data (With Pallet Changer) | ||||

| Basic machine weight | kg | 14000 | 24000 | 30000 |

| Floor area W x D | mm | 3200x5800 | 4250x7000 | 4500x9500 |

| Compressed Air | bar | 5-6 | 5-6 | 5-6 |

| Total connected load-cont/ 30 min | kVA | 60 | 90 | 100 |

| Power supply | 3ph, 415 V, 50 Hz | |||

| CNC system | Siemens Sinumerik 1(Simultaniuos 5 axis) | |||

Applications

Have Any Question?

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Follow us on

PRODUCTS

RESOURCES

BFW UPDATES

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Copyright 2026 © BFW, Designed & Developed by Appac Mediatech Pvt Ltd

Get Quote

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Download the brochure

Download our comprehensive product brochure and learn how our products should support your needs.