Swaging Machine for Banjo Beam Ends Roundness Correction

Customer Challenge Banjo beams are critical automotive components (EN36 Steel) made by welding two halves together. After this, the beam is welded to the wheel

Customer Challenge Banjo beams are critical automotive components (EN36 Steel) made by welding two halves together. After this, the beam is welded to the wheel

Component Defence Part Operations Drilling, Milling, Finish Boring & Tapping The Challenge A leading player in the defence sector faced a critical machining challenge for

Component Banjo Beam (1000-2000 mm Length) Operations Milling, Boring, Drilling & Taping The Customer Challenge A leading automotive OEM was facing a significant machining challenge

Overview A leading automotive component manufacturer required a high-precision machining solution for wheel plate assemblies. The challenge was to deliver consistent machining performance across multiple

Client A leading scooter manufacturer renowned for precision-engineered mobility solutions. Component Camshaft – A critical engine component that controls the opening and closing of intake

About the Client A leading joint venture manufacturer of forged components, primarily serving the automotive sector with complex and critical parts such as crankshafts. Known

Introduction Case study of BFW solving critical challenges of a component manufacturer seeking a comprehensive solution for the production of pin shift finger machining solution.

Introduction A front axle beam is a component that plays a critical role in automotive engineering. It connects the front wheels of a vehicle, supports

An external pin milling machine is used to manufacture machine tools designed for machining external cylindrical surfaces, pins and shafts, among others. This process is

Crank and cam are essential components that convert and convert motion in machines, respectively. A crank enables converting linear motion into rotation motion or vice

A clutch cover is a casing or shield designed to encase and protect the components of a vehicle’s clutch system. This cover safeguards the clutch

Case study of BFW solving critical challenges of a two wheeler manufacturer seeking customised solutions for the production of cylinder blocks for its two wheelers.

Valves are critical components in various industries, regulating the flow of fluids or gases within a system. Automation in valve assembly involves the integration of

The PSA intermediate shaft machining line is designed to ensure high-quality and precise component manufacturing. An intermediate shaft machining line refers to a production facility

Introduction Drum brakes are a significant component in vehicle systems, featuring brake shoes that exert force on the rotating drum wall to halt motion. This

The chain case is a critical component within vehicles. It provides a covering for the chain responsible for power transmission from the engine to the

Introduction Punching on a fuel tank refers to the manufacturing process of creating holes, perforations, or openings in a fuel tank using specialised machinery or

Introduction Our client operates within the die casting foundry industry. The process of die casting involves the injection of molten metal into moulds or dies.

BFW’s customer is a precision components manufacturing solutions company. They cater to various industries, including aerospace, general engineering, and electronic segments. The company’s manufacturing facility

Introduction The term “case transaxle” refers to an integral component within an automotive transaxle system that combines the functions of a transmission and axle into

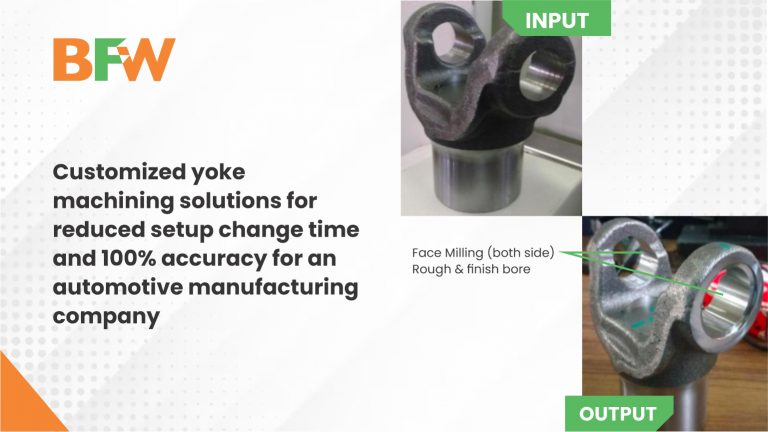

Customised yoke machining solutions for reduced setup change time and 100% accuracy for an automotive manufacturing company. Introduction In automotive manufacturing, a yoke component is

Introduction A prominent automotive manufacturer specializing in production of advanced braking systems, aluminum lightweighting precision solutions, and safety control cables embarked on a mission to

Nelcast is the Largest Jobbing Foundry in India for the manufacturing of Ductile & Grey Iron Castings. Established in 1982 with a modest capacity of

BFW VMC’s Delivers Precision, Reliability for Growing Mould Base Business Mould Base Machining M/s Orange City Alloys Pvt Ltd is one of the leading steel

Company: SB Patterns Product Range: Pattern machining, Shell moulded component machining, general engineering. SB Pattern, one of the well-known pattern makers in Belgaum Karnataka, started

To meet the demand for ‘world-class’ HMCs for the Indian and global market, BFW has developed the Orion-series of next-gen HMCs. To meet the demand

Bharat Fritz Werner Ltd. (BFW) is a pioneering name in machine tools, manufacturing solutions, and technological innovation.

Subscribe to get notified about latest events, new products, industry insights and other updates from BFW, directly to your inbox.

Trusted Global Manufacturing Technology Partner

Are you looking for a product or service offer? Let us know your requirements and we will get back to you soon.

We will get back to you soon

Kindly complete the form with the required information